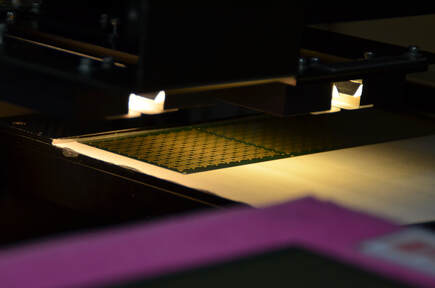

AUTOMATED VISUAL INSPECTIONUsing high technology machine, printed circuit board is automatically inspected to detect non-conforming units with the use of high-definition camera connected to a computer to capture and process images and with the use of set standard for pattern measurement based on customer specification.

|

FINAL VISUAL INSPECTIONIn Final Visual Inspection process, Printed Circuit Board is 100% inspected under stereoscopic microscopes with a magnification from 8-50x, by high-skilled inspectors mostly trained in Japan to ensure that all non-conforming units are identified and properly marked out to meet all quality requirements based on customer specifications and criteria.

|

QUALITY ASSURANCE CHECK PROCESSIn order to determine the compliance of product to the customer requirement and specification, Quality Assurance Department conducts sampling inspection and necessary checking to the product before delivery and ship out to the customer. Quality Assurance Department use acceptance criteria to evaluate the conformity of product to the standard.

|

PLASMA CLEANING PROCESSA cleaning system process that involves the removal of impurities and contaminants from surfaces of the PCB through the use of an energetic plasma or dielectric barrier discharge (DBD) plasma created from gaseous species such as oxygen and argon. Once cleaning is done, wiring pattern's surface energy will increase also its adhesive characteristics which will make the wire bonding process much easier.

|

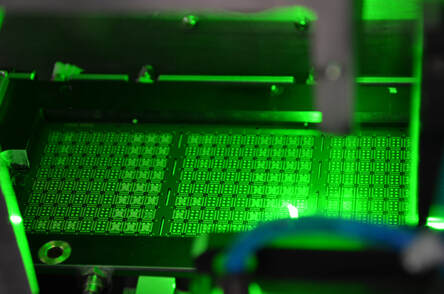

LASER MARKING PROCESSBy the use of eco-friendly Green Laser Marking Machine and Carbon Dioxide Technology, all detected non-conforming units of the PCB from AVI and FVI process were permanently marked using high powered laser with specific sizes, appearance and power ranges set according to customer requirement.

|

ULTRASONIC WASHING PROCESSA cleaning process that held product in between conveyorized net to ensure cleaning and removal of foreign materials from top to bottom of the PCB. It uses ultrasonic waves and de-ionized water as cleaning solvent to wash surfaces of the PCB and a high pressure blow of air to blow water after washing.

|